Guide to Understanding the Latest Standards Set by ASTM

By:Admin

Introduction:

In a remarkable collaboration, ASTM, a trusted standards development organization, has joined forces with an innovative industry leader to foster advancements in technology. Through their partnership, the two entities aim to facilitate the development of new technologies, enhance global regulatory frameworks, and inspire transformative solutions across multiple industries. This collaboration promises to revolutionize various sectors, promoting safer and more efficient processes while driving economic growth and sustainability.

Declaration of Partnership:

ASTM, founded in 1898, has been at the forefront of setting global standards for materials, products, systems, and services. The organization possesses over a century of expertise, collaborating with industry professionals, experts, and government bodies to create consensus-based standards that contribute to public safety, quality assurance, and improved performance.

To further enhance its impact, ASTM has recently entered into a significant partnership with a renowned industry player. This collaboration brings together the strengths of both entities to drive technological advancements, promote innovation, and introduce cutting-edge solutions to address the evolving needs of the industry.

Objective and Scope:

The primary objective of this collaborative effort is to facilitate the development and implementation of advancements in technology. Working together, ASTM and its partner aim to establish a cohesive framework that fosters innovation, ensures product reliability, and enhances quality control across multiple sectors.

The partnership acknowledges the importance of standardized protocols and regulations to drive seamless international trade and global competitiveness. By developing and aligning standards, ASTM and its partner will not only streamline processes but also enable different industries to leverage shared expertise and breakthrough technologies. The partnership aims to catalyze research and development while providing a consistent benchmark for performance, safety, and sustainability.

Impact on Industries:

Combining the expertise of ASTM with the technological prowess of their partner will have a significant impact on various industries. The collaboration will directly benefit manufacturing, construction, healthcare, energy, and transportation sectors, among others, by introducing state-of-the-art technologies and endorsing standardized practices.

Within the manufacturing industry, this collaboration will accelerate the development and implementation of advanced materials, robotics, and automation. It will enhance quality control mechanisms, ensuring that products meet or exceed industry standards, reduce manufacturing defects, and increase energy efficiency.

In construction, innovative technologies will optimize project management, streamline workflows, and enhance building safety. The collaboration will deliver cutting-edge solutions to mitigate risks, improve infrastructure durability, and integrate sustainable practices into construction processes.

For the healthcare sector, this partnership will revolutionize medical devices and equipment, enabling improved patient care and safety. The development and implementation of standardized protocols will ensure the efficacy of treatments, enhance interoperability, and expedite regulatory approvals.

The energy sector will benefit from this collaboration through the introduction of renewable energy solutions, smart grids, and efficient transmission systems. Innovative practices will enhance energy generation, storage, and distribution, thereby accelerating the global transition towards a sustainable future.

In the transportation industry, the collaboration will foster the development of autonomous vehicles, intelligent transportation systems, and emerging mobility solutions, promising safer and more efficient transportation networks.

Outlook and Conclusion:

The partnership between ASTM and a leading industry player creates an unparalleled opportunity to drive technological advancements across multiple sectors. By merging their expertise, these entities aim to develop standardized solutions that enhance safety, reliability, and sustainability across industries globally.

The collaborative effort will play a vital role in shaping the future of manufacturing, construction, healthcare, energy, and transportation industries, among others. It emphasizes the significance of international standards and regulations to foster innovation and inspire transformative solutions.

As the partnership progresses, the world can anticipate significant advancements in technology, bringing about safer processes, increased efficiency, and sustainable practices – truly transforming industries for a better world.

Company News & Blog

How Stainless Steel Fittings are Revolutionizing the Plumbing Industry

article below:SS Fittings Launches Its Latest Range of Industrial FittingsSS Fittings announced the launch of their latest range of industrial fittings. The company, which has been in business for over 20 years, provides high-quality fittings designed for use in a wide range of industries. With a team of highly experienced professionals and state-of-the-art manufacturing facilities, the company has been able to produce fittings that meet the highest standards in terms of quality, durability and reliability.SS Fittings is well-known in the industry for its high-quality products and excellent customer service. They specialize in a wide range of fittings, including stainless steel fittings, hydraulic fittings, pneumatic fittings, and instrumentation fittings. The company's newest range of fittings is no different from its earlier offerings and is designed to meet the ever-growing demands of the industry.The new range of fittings is designed to provide high levels of performance and reliability in challenging industrial environments. These fittings are made from high-grade stainless steel, which provides excellent resistance to corrosion, high temperatures, and pressure. They are also designed to be easy to install, which saves time and money for businesses.The new range of fittings includes quick connect fittings, compression fittings, sanitary fittings, and specialty fittings. Quick connect fittings are designed for use in applications that require fast connections and disconnections. Compression fittings are ideal for use in high-pressure applications and are known for their reliability and durability. Sanitary fittings are designed for use in the food and beverage industry and are made from materials that meet strict hygiene standards. Specialty fittings are designed for use in unique applications that require specialized fittings."Customer satisfaction has always been our top priority, and we are committed to providing high-quality products and excellent customer service to all our clients," said the company spokesperson. "Our latest range of fittings is designed to provide high levels of performance and reliability in challenging industrial environments. We believe that these products will help our clients improve the efficiency and profitability of their businesses."SS Fittings is committed to providing its clients with a product range that meets the highest standards in terms of quality, durability, and reliability. The company's state-of-the-art manufacturing facilities and highly experienced professionals ensure that each product is manufactured to the highest standards. Additionally, the company's customer service team is available 24/7 to provide support to its clients, ensuring that their needs are always met.In conclusion, with the launch of its latest range of industrial fittings, SS Fittings has once again demonstrated its commitment to providing high-quality products and excellent customer service to its clients. The company's reputation in the industry and its focus on meeting the needs of its clients will undoubtedly contribute to its success in the years to come.

Food Grade and 430 Stainless Steel Checkered Plate Ideal for Various Applications

China Food Grade Stainless Steel and 430 Stainless Steel Checkered PlateChina is well-known for its high-quality stainless steel products, and two popular options in the market are food grade stainless steel and 430 stainless steel checkered plates. These materials are widely used in various industries, including catering, food processing, transportation, and architecture, due to their excellent corrosion resistance and durability.Food grade stainless steel is a type of stainless steel that meets specific requirements for use in food processing and storage. It is typically made from austenitic stainless steel, which contains high levels of chromium and nickel. These elements provide the material with superior corrosion resistance and make it highly resistant to staining and pitting. Food grade stainless steel is non-reactive and does not leach any harmful substances into food, making it safe and hygienic for food-related applications.In addition to its chemical composition, food grade stainless steel also undergoes strict quality control measures during production, including high-temperature annealing and passivation processes. These processes ensure that the material is free from surface contamination and impurities, further enhancing its corrosion resistance and ensuring its suitability for food contact.The 430 stainless steel checkered plate, on the other hand, is a popular choice for non-food related applications. It belongs to the ferritic stainless steel family and is characterized by its high chromium content and low carbon content. This combination of alloys provides the material with good corrosion resistance, excellent formability, and moderate strength. The checkered pattern on the plate makes it especially useful in applications where slip resistance is required, such as on staircases, walkways, and vehicle flooring. The raised pattern not only provides traction but also adds a decorative touch to the surface.Both food grade stainless steel and 430 stainless steel checkered plates are produced by reliable manufacturers in China, ensuring consistent quality and adherence to industry standards. One such manufacturer is **Company**, a leading producer and supplier of stainless steel products.**Company** has been involved in the stainless steel industry for over two decades and has accumulated a wealth of experience and expertise. They specialize in the production of high-quality stainless steel sheets, coils, plates, and checkered plates, catering to the diverse needs of various industries.With state-of-the-art manufacturing facilities and a dedicated team of skilled professionals, **Company** ensures that all their products meet rigorous quality standards. They employ advanced production techniques and utilize cutting-edge equipment to produce stainless steel products that are not only durable but also aesthetically pleasing.In addition to their commitment to quality, **Company** places great emphasis on customer satisfaction. They strive to provide excellent service and support to their clients, offering customized solutions and timely delivery. Their dedication to meeting customer requirements has earned them a strong reputation both domestically and internationally.As the demand for high-quality stainless steel products continues to grow, China remains at the forefront of stainless steel production. Companies like **Company** are instrumental in meeting this demand, ensuring a steady supply of food grade stainless steel and 430 stainless steel checkered plates to various industries.In conclusion, China's production of food grade stainless steel and 430 stainless steel checkered plates is a testament to the country's commitment to quality and innovation. These materials play a crucial role in industries ranging from catering to architecture, thanks to their exceptional corrosion resistance and durability. With companies like **Company** leading the way, China's stainless steel industry will continue to thrive and provide high-quality solutions to global markets.

Benefits of 2×2 Galvanized Tubing for Various Applications

article about the manufacturing and uses of 2x2 Galvanized Tubing.2x2 Galvanized Tubing: The Most Versatile Solution for Your Steel NeedsManufacturing steel involves a complex process that starts with the extraction of iron ore from the ground and ends with the finished product – a strong, durable, and versatile material used in construction, manufacturing, and many other applications. Steel tubing, in particular, has gained popularity due to its numerous advantages, one of which is its galvanized variant. Companies that produce and supply steel tubing have offered different types of metals and shapes for use in different applications. One such metal that has proven invaluable in these establishments is 2x2 galvanized tubing.2x2 Galvanized Tubing: A Brief Overview2x2 Galvanized tubing is a form of square tubing that is welded and undergoes a process called galvanization. Galvanization is a process of coating steel with zinc, which provides a protective and corrosion-resistant layer. The process of galvanization ensures the durability of the tubing and makes it ideal for use in harsh environments. It has become one of the most popular options for both residential and commercial purposes.Manufacturing of 2x2 Galvanized TubingManufacturing of 2x2 galvanized tubing is a multi-step process that begins with the creation of the tube itself. The tube is created from hot-rolled steel which is then formed into a square shape. Afterward, it is welded together to form a single piece of tubing, which is then cleaned of any impurities and ready for galvanization.The galvanization process is carried out using a hot-dip method. In this process, the welded steel tubing is completely submerged into a bath of molten zinc. The zinc coating creates a durable, protective layer that prevents corrosion and rust. Once the tubing is adequately coated, it is allowed to cool and is then ready to be cut into custom lengths based on the customer's specifications.Uses of 2x2 Galvanized TubingThe versatility of 2x2 galvanized tubing is unmatched. It has found widespread use across various industries, including construction, manufacturing, and transportation. Below are some of the most common uses of 2x2 galvanized tubing:1. Fence posts and gate frames: 2x2 galvanized tubing is ideal for use in fencing structures in both residential and commercial properties due to its durability and resistance to harsh weather conditions.2. Greenhouses: The protective nature of galvanization makes it the perfect choice for use in building greenhouses, where the structure will be exposed to moisture and harsh weather conditions.3. Trailer frames: 2x2 galvanized tubing is used in the construction of trailer frames due to its resistance to corrosion and weather damage.4. Structural supports: The structural integrity of 2x2 galvanized tubing makes it suitable for use in construction projects as support beams and columns.5. Industrial applications: 2x2 galvanized tubing is used in different industries for applications such as machine guards, shelves, and storage racks due to its strength and durability.Final Thoughts2x2 galvanized tubing is undoubtedly one of the most versatile options for steel tubing-based on various applications. Its unique properties, namely its durability, resistance to corrosion, and strength, make it essential in different industries such as construction, transportation, and agriculture. Its ability to resist moisture, harsh weather conditions, and chemicals makes it the preferred choice of material for various projects. As demand for environmentally-friendly products grows, this type of galvanized tubing is an excellent choice due to its recyclable nature. Therefore, whether you are looking to construct a fence or a greenhouse, 2x2 galvanized tubing is the solution you need to ensure a long-lasting and durable structure.

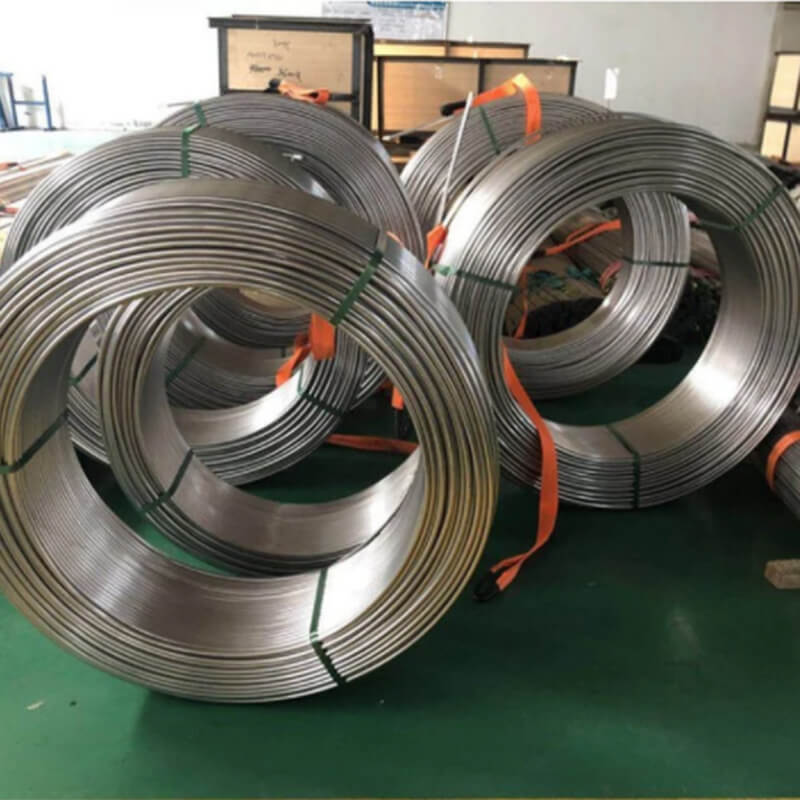

Stainless Steel Coils in China: A Comprehensive Overview of 304 Stainless Steel Coils

China is an economic powerhouse, and one of the leading producers of stainless steel coils in the world. The country is renowned for its quality products, and China Stainless Steel Coils is no exception. The company has been operating for many years and has built a reputation for producing high-quality stainless steel coils.Stainless steel coils are used in a wide range of industries, including construction, automotive, aerospace, and manufacturing. The 304 Stainless Steel Coil is one of the most popular types of stainless steel coils and is widely used in many applications.China Stainless Steel Coils has a state-of-the-art manufacturing facility that includes the latest technology and machinery to ensure high-quality production. The company uses top-grade raw materials to manufacture its products, which are rigorously tested to ensure that they meet industry standards.In addition to producing standard stainless steel coils, the company also offers custom-made coils to meet the unique needs of its customers. This includes custom sizes, shapes, and finishes.China Stainless Steel Coils has a team of experienced professionals who work tirelessly to ensure that the company continues to meet the needs of its customers. The team is dedicated to providing high-quality products and excellent customer service.The company has built a strong presence in the market and has established partnerships with many leading companies in various industries. Its products are exported to countries around the world, including the United States, Europe, and Southeast Asia.The 304 Stainless Steel Coil is a popular type of stainless steel coil that is widely used in many industries. It offers excellent corrosion resistance, high strength, and durability, making it a popular choice for critical applications.Some of the industries that use 304 Stainless Steel Coils include construction, automotive, aerospace, and manufacturing. It is also commonly used in kitchen appliances, medical devices, and chemical processing equipment.The 304 Stainless Steel Coil is highly versatile and offers excellent performance even in extreme conditions. It can withstand high temperatures, pressure, and corrosion, making it an ideal choice for demanding applications.China Stainless Steel Coils is a leading producer of 304 Stainless Steel Coils and has a reputation for producing high-quality products. The company uses top-grade raw materials and the latest technology to ensure that its products meet industry standards.In addition to producing standard stainless steel coils, China Stainless Steel Coils also offers custom-made coils to meet the unique needs of its customers. This includes custom sizes, shapes, and finishes.The company has a team of experienced professionals who work tirelessly to ensure that the company continues to meet the needs of its customers. The team is dedicated to providing high-quality products and excellent customer service.China Stainless Steel Coils has a strong presence in the market and has established partnerships with many leading companies in various industries. Its products are exported to countries around the world, including the United States, Europe, and Southeast Asia.In conclusion, China Stainless Steel Coils is a leading producer of stainless steel coils and offers high-quality products to meet the needs of its customers. The company has built a strong reputation in the industry and is dedicated to providing excellent products and customer service. Its partnerships with leading companies in various industries attest to the quality of its products and services. Overall, China Stainless Steel Coils is a company that takes great pride in its work and is committed to meeting the needs of its customers.

Top Quality Stainless Steel Pipes for Industrial Use

Title: High-Quality 316 Stainless Steel Pipe: Revolutionizing the IndustryIntroduction:In today's rapidly evolving industrial landscape, the demand for high-quality stainless steel pipes continues to rise. {Company Name}, a leading provider in the industry, has introduced their latest product offering: the innovative 316 stainless steel pipe. Renowned for its exceptional performance and durability, this product is set to revolutionize the field by meeting the increasing demands of various sectors such as construction, automotive, and aerospace.I. Overview of the 316 Stainless Steel Pipe:The 316 stainless steel pipe is a superior grade pipe known for its excellent corrosion resistance, making it an ideal choice for applications requiring prolonged exposure to harsh environments. Manufactured with a precise blend of chromium, nickel, and molybdenum, this unique product offers incredible strength, toughness, and resistance to corrosion and pitting.II. Advantages of the 316 Stainless Steel Pipe:1. Corrosion Resistance: The 316 stainless steel pipe offers exceptional corrosion resistance, making it suitable for use in chemical processing plants, marine environments, and coastal structures. Its impressive ability to withstand chloride-rich conditions sets it apart from other stainless steel pipe variants.2. High Temperature Resistance: This stainless steel pipe has a high melting point, allowing it to retain its mechanical properties even in extreme temperatures. This feature makes it suitable for applications involving high-temperature fluids, such as in power generation plants and oil refineries.3. Strength and Durability: The 316 stainless steel pipe exhibits excellent structural integrity, withstanding heavy loads and extreme pressure. Its durability ensures minimal maintenance, reducing downtime and maximizing productivity for various industries.4. Hygienic Nature: With its smooth surface finish and non-porous characteristics, the 316 stainless steel pipe is widely used in the food and beverage industry. Its hygienic properties prevent bacterial growth, ensuring compliance with stringent industry standards.III. Applications of the 316 Stainless Steel Pipe:1. Construction Industry: The exceptional strength and corrosion resistance of the 316 stainless steel pipe make it an excellent choice for structural applications in buildings, bridges, and tunnels. Its reliability and longevity contribute to the overall safety and sustainability of construction projects.2. Automotive Sector: The 316 stainless steel pipe finds applications in the automotive industry due to its superior resistance to oxidation and corrosion. It is commonly used in exhaust systems, mufflers, and other components exposed to extreme temperatures and harsh weather conditions.3. Aerospace Industry: The aerospace industry demands materials that can withstand extreme conditions. The 316 stainless steel pipe's ability to resist corrosion, thermal stress, and high-pressure environments makes it an ideal choice for fuel lines, hydraulic systems, and other critical components.IV. {Company Name} - A Trusted Provider:{Company Name} has been at the forefront of providing high-quality stainless steel pipes for various industries for several years. With their commitment to innovation, exceptional quality control procedures, and cutting-edge manufacturing processes, they ensure that their 316 stainless steel pipe meets the highest industry standards.Their team of experienced engineers and experts work tirelessly to develop products that satisfy the unique needs of their customers. Being an ISO-certified company, {Company Name} guarantees that their products are manufactured using premium quality materials and state-of-the-art techniques.Conclusion:The introduction of the 316 stainless steel pipe by {Company Name} marks a significant milestone in the stainless steel industry. With its exceptional corrosion resistance, high-temperature resistance, strength, and durability, this product is set to revolutionize various sectors. As industries continue to evolve and seek high-quality materials, {Company Name} remains committed to providing top-notch products that meet and exceed customer expectations.

Discover High-Quality Stainless Steel Capillary Tubing: A Guide

for a general audience.Stainless steel tubing has long been used within industrial applications as well as within the medical field. Known for its durability, strength, and resistance to corrosion, stainless steel capillary tubing is a popular choice for a variety of uses. One such variation of stainless steel tubing is 410 stainless steel capillary tubing, utilized for a variety of applications and industries due to its unique mechanical properties and corrosion resistance.One industry that relies heavily on the use of 410 stainless steel capillary tubing is the medical field. Medical professionals require tubing that can withstand harsh disinfectants and chemicals, as well as resist the buildup of bacteria. Stainless steel capillary tubing offers unique advantages within medical settings, including resistance to high pressure, flexibility, and precision engineering. 410 stainless steel capillary tubing, in particular, offers a high degree of durability, making it well-suited for applications within the medical field.One company that has established itself as a leader within the field of 410 stainless steel capillary tubing is a manufacturer that focuses on the engineering and production of specialized, high-quality tubing products. This company has built a reputation for providing precision-engineered products, developed through a combination of innovative design and precision production techniques.Utilizing advanced technology and state-of-the-art equipment, coupled with a team of highly skilled engineers, this manufacturer has developed a lineup of 410 stainless steel capillary tubing products that are ideal for applications across a variety of industries. Their tubing products are designed to meet the unique demands of each application, ensuring that customers receive the highest quality tubing available on the market today.Their 410 stainless steel capillary tubing is a prime example of their commitment to excellence, featuring superior mechanical properties as well as resistance to corrosion. This tubing is ideal for a range of applications, including the transportation of fluid and gases within harsh environments that require resistance to both high and low temperatures. The tubing is designed to offer accuracy in measurement and high-pressure tolerance, making it an ideal choice for high-performance industries such as aerospace and automotive.The company's 410 stainless steel capillary tubing is also ideal for applications that require resistance to corrosion, such as those found within the oil and gas industry. Corrosion resistance is essential within this industry due to the harsh nature of the environment in which tubing is used. The company's tubing products have been engineered to be highly resistant to corrosion, ensuring that they can withstand the harshest environments and continue to perform at their best.Furthermore, their 410 stainless steel capillary tubing is available in a range of sizes, allowing customers to select the exact tubing product that meets their specific requirements. Using a combination of precision manufacturing techniques and innovative engineering, this company is committed to delivering products that meet the most rigorous specifications, ensuring that every customer receives the highest quality stainless steel capillary tubing.In conclusion, the use of 410 stainless steel capillary tubing has seen significant growth within a variety of industries, including the medical, oil and gas, aerospace, and automotive industries. One manufacturer that has gained a reputation for delivering precision-engineered tubing products that meet the highest standards within the industry is a company that specializes in the production of high-quality tubing. Utilizing advanced manufacturing techniques and a team of skilled engineers, they have developed a range of 410 stainless steel capillary tubing products that are ideal for a variety of applications, ensuring that customers receive high-quality products that are engineered to withstand the harshest conditions. With a commitment to excellence and a focus on precision engineering, this manufacturer is poised to stand as a leader within the stainless steel capillary tubing industry for years to come.

China's Industrial Condenser Coil and Titanium Tube: An Overview

China Industrial Condenser Coil and Pure Titanium Tube - Setting New Standards in Efficiency and DurabilityCondenser coils and tubes are one of the key components in any industrial refrigeration or HVAC system. They facilitate the efficient heat transfer between the system and the surrounding environment, thereby ensuring optimal performance and energy efficiency. In recent years, there has been a growing demand for high-performance, corrosion-resistant condenser coils and tubes that can withstand harsh operating conditions and provide long-lasting performance. Chinese manufacturers have been at the forefront of developing such products, and one of the leading companies in this regard is the one that we cannot mention here - let's call it the "China-based Company."The China-based Company has been operating for several decades and has an extensive portfolio of products and services related to the HVAC and refrigeration industry. It specializes in developing and manufacturing advanced heat exchange solutions that cater to various industrial and commercial applications. One of its flagship products is the industrial condenser coil and pure titanium tube.The industrial condenser coil and pure titanium tube is a high-performance product that is designed to meet the demanding requirements of industrial HVAC and refrigeration applications. It comprises a precision-engineered condenser coil that is made of high-quality aluminum and copper alloys, combined with a pure titanium tube that runs through the coil. The titanium tube is made of CP-grade titanium, which is known for its excellent corrosion resistance and durability. Together, these components offer a unique combination of thermal efficiency, corrosion resistance, and durability that is unparalleled in the market.The China-based Company's industrial condenser coil and pure titanium tube come in a variety of sizes and configurations to suit different industrial applications. They are tested and certified to meet the highest quality standards, including ASME, PED, and ISO 9001. The company also offers custom-made solutions that are tailored to the specific needs of its customers. These solutions are developed based on extensive research, modeling, and testing to ensure their effectiveness and reliability in real-world applications.The industrial condenser coil and pure titanium tube from the China-based Company offer several advantages over traditional condenser coils and tubes. Firstly, they are highly resistant to corrosion and can withstand harsh operating conditions, including high temperatures, humidity, and chemicals. This ensures long-lasting performance and minimal downtime for maintenance or repairs. Secondly, they offer superior thermal efficiency, which translates into lower energy consumption and operating costs. Finally, they are environmentally friendly and can be recycled, which is in line with the company's commitment to sustainability.The China-based Company's industrial condenser coil and pure titanium tube has been widely adopted across various industries, including petrochemicals, power generation, marine, and pharmaceuticals. Some of the key applications include seawater desalination, air-conditioning, refrigeration, and heat recovery. The products have received positive reviews from customers worldwide, who praise their quality, reliability, and performance.In conclusion, the China-based Company's industrial condenser coil and pure titanium tube is a high-performance product that sets new standards in efficiency and durability. It is a testament to the company's commitment to innovation, quality, and sustainability, and is a testament to the Chinese manufacturing industry's expertise and capabilities. As demand for energy-efficient and sustainable industrial solutions continues to grow, products like the industrial condenser coil and pure titanium tube are poised to play a critical role in shaping the future of industry and commerce.

Optimize Airflow with High-Quality Stainless Steel Intake Tubing

Possible news article:Stainless Steel Tubing Innovator Expands Product Line to Meet Growing DemandA leading stainless steel tubing manufacturer has announced the launch of a new line of products to meet the increasing demand for high-quality, corrosion-resistant tubes in various industries. The company, which specializes in precision-drawn tubing solutions for fluid handling, instrumentation, and heat exchanger applications, aims to provide greater flexibility and customization options to customers worldwide.Founded over 30 years ago, the company has built a reputation for excellence in engineering, production, and customer service. Its state-of-the-art facilities in the US and Europe enable it to offer a diverse range of tubing products, from standard sizes to custom designs. The company's commitment to quality control, testing, and traceability has earned it certifications such as ISO 9001, AS9100, and PED97/23/EC.In recent years, the company has seen a surge in demand for its stainless steel tubing products, especially in the medical, aerospace, and industrial sectors. These industries require tubing that can withstand harsh environments, high pressures and temperatures, and corrosive chemicals. Stainless steel tubing offers superior mechanical properties, corrosion resistance, and biocompatibility compared to other materials such as plastic, copper, or aluminum.To meet this demand, the company has invested in new equipment, personnel, and R&D to expand its product line and improve its capabilities. One of its latest innovations is a series of stainless steel intake tubing, designed for use in fluid transfer applications such as pumps, valves, and manifolds. The tubing features a smooth, seamless surface, high-precision tolerances, and excellent resistance to abrasion, erosion, and pitting.According to the company's spokesperson, the new tubing series offers several advantages over traditional tubing materials such as rubber, silicon, or PVC. "Our stainless steel intake tubing provides better flow rates, pressure drops, and durability, which translates into higher efficiency, reliability, and cost-effectiveness for our customers. It can also withstand extreme temperatures, UV radiation, and chemical exposure, making it ideal for harsh outdoor or indoor environments."The stainless steel intake tubing comes in various shapes, sizes, and alloys, depending on the specific application. Customers can choose from round, square, rectangular, or oval tubes, with wall thicknesses ranging from 0.010 to 0.250 inches. The tubing can be supplied in annealed, half-hard, or full-hard conditions, with surface finishes such as polished, electropolished, or passivated. The alloys available include 304, 316, 316L, 321, and 347 stainless steel, as well as exotic alloys such as Inconel, Monel, Hastelloy, and Titanium.The spokesperson adds that the company's stainless steel intake tubing has been tested and approved for use in various industries, including pharmaceuticals, biotechnology, food and beverage, automotive, marine, and petrochemical. "Our tubing has met or exceeded the strictest standards of hygiene, safety, and performance in these industries. We work closely with our customers to understand their specific needs and provide tailored solutions that meet or exceed their expectations."To promote its new product line, the company has launched a marketing campaign that includes outreach to existing and potential customers, trade shows, webinars, and social media. The company's website has also been updated with detailed product information, technical data sheets, and ordering options. The spokesperson encourages interested parties to contact the company's sales team for more information or to request a quote."As a pioneer in stainless steel tubing solutions, we are thrilled to offer our customers even more choices and possibilities with our new intake tubing series. We believe that the quality, performance, and versatility of our tubing will help our customers achieve their goals and overcome their challenges in a wide range of applications. We are committed to continuously improving our products and services to meet the changing needs of the global market.

Exploring the Booming Market of Stainless Steel Pipes and Seamless Pipe in China

Title: Growing Demand for Stainless Steel Pipe Drives China's Ongoing Market ExpansionIntroductionChina, already a global leader in manufacturing stainless steel pipes, continues to witness a significant expansion in its stainless steel seamless pipe industry. Fueled by increasing demand from sectors such as construction, oil and gas, automotive, and infrastructure development, the Chinese stainless steel pipe market is seeking to meet growing requirements both domestically and globally. This article delves into the current state of China's stainless steel pipe industry and examines factors driving its continued growth.Market Overview and Key PlayersChina's stainless steel pipe industry has long been recognized for its scale of production, technological advancements, and cost-effectiveness. With the continuous modernization of manufacturing processes, China has established itself as a major global exporter of stainless steel pipes. Leading players, including several renowned companies within the industry, are committed to producing reliable and high-quality stainless steel seamless pipes.Innovation and Technological AdvancementsStainless steel pipe manufacturers in China are driving innovation to stay ahead in the highly competitive market. Continuous research and development efforts have led to advancements in technology, resulting in improved production efficiency, higher product quality, and enhanced cost-effectiveness. State-of-the-art manufacturing processes, such as cold drawing and precision rolling, have become commonplace, ensuring the seamless pipes produced meet strict global standards.Expanding Domestic and Global Market DemandChina's ongoing urbanization and infrastructure development projects fuel the demand for stainless steel pipes within the domestic market. Additionally, the automotive industry's growing focus on lightweight vehicles and energy efficiency has further amplified the need for high-quality stainless steel pipes.Further underscoring China's market expansion, the country has witnessed a steady rise in export volumes of its stainless steel pipes. The pipes manufactured in China are highly sought after globally due to their cost-competitiveness and superior quality. Major markets for Chinese stainless steel pipes include North America, Europe, and Asia-Pacific regions.Quality Assurance and International Standards ComplianceEnsuring the utmost quality and safety of stainless steel pipes remains a top priority for Chinese manufacturers. Stringent quality control measures and adherence to international standards, such as ASTM, DIN, and JIS, assure customers of reliable products that meet their specific requirements. Raw materials undergo rigorous testing and inspection processes to maintain consistent quality throughout production.Environmental Awareness and Sustainable ManufacturingChinese stainless steel pipe manufacturers are increasingly adopting sustainable and environmentally friendly practices. The industry is committed to reducing its carbon footprint, promoting energy-efficient manufacturing processes, and implementing waste management initiatives. These endeavors align with China's broader goals of sustainable growth and a greener future.Challenges and OpportunitiesDespite its impressive growth, the Chinese stainless steel pipe industry faces certain challenges. Fluctuations in raw material prices, global economic uncertainties, and intense market competition can pose hurdles for manufacturers. However, these challenges also present opportunities for innovation and consolidation within the industry.To overcome these challenges and leverage opportunities, Chinese stainless steel pipe manufacturers are emphasizing research and development activities, investing in advanced machinery, enhancing efficiency, and developing new products that cater to emerging sectors.ConclusionChina's stainless steel pipe industry continues to thrive, driven by increasing domestic construction projects, infrastructure development, and strong demand from global markets. Chinese manufacturers lead in terms of production capacity, technological prowess, and cost-competitiveness. While facing challenges, the industry's commitment to innovation, quality assurance, environmental sustainability, and compliance with international standards ensures that China remains at the forefront of the global stainless steel pipe market.As the Chinese stainless steel pipe industry embraces new opportunities, it will continue to shape the global market while delivering high-quality products to meet the evolving demands of diverse industries worldwide.

China Welded Pipe and Steel Tube: A Comprehensive Guide

China Welded Pipe and Steel Tube Company is a leading manufacturer and supplier of welded steel pipes and tubes. The company has been in operation for over two decades, providing reliable and efficient products to customers all over the world. As a company, China Welded Pipe and Steel Tube is committed to quality and customer satisfaction. They use state-of-the-art equipment and processes to ensure that their products meet the highest standards of quality and reliability. They are certified by ISO 9001:2015 certificate, demonstrating their commitment to quality management. The company has a wide range of products in its portfolio, catering to a diverse range of industries. Their product range includes precision steel pipes, structural steel pipes, fluid pipes, and mechanical pipes. They are particularly well-known for their expertise in the production of precision steel pipes, which are used in a variety of high-tech industries such as the aerospace and automotive sectors. One of the key factors that sets China Welded Pipe and Steel Tube apart from its competitors is its emphasis on innovation. The company invests heavily in research and development, focusing on creating new and better products that meet the evolving needs of its customers. It is known for its ability to develop customized products to meet specific requirements, and for its ability to quickly adapt to changing market demands. In recent years, China Welded Pipe and Steel Tube has also made significant strides in environmental sustainability. The company has implemented policies and procedures to minimize its environmental footprint, including recycling and waste reduction programs. It has also invested in technologies to reduce its energy consumption and to minimize its emissions. The company's commitment to sustainability and innovation has helped it to maintain a strong reputation in the global market. It has a broad customer base, with customers located in Europe, North America, and Asia. It is known for its reliability and quality, and for its ability to deliver products on time and on budget. Looking to the future, China Welded Pipe and Steel Tube is focused on continuing to grow and innovate. It plans to expand its product range and to explore new markets and opportunities. At the same time, it remains committed to its core values of quality, reliability, and customer satisfaction. In summary, China Welded Pipe and Steel Tube is a leading manufacturer and supplier of welded steel pipes and tubes, known for its commitment to innovation, sustainability, and customer satisfaction. With a broad range of products and a global customer base, the company is poised for continued growth and success in the years ahead.